e-path sustainable transportation

Abundant wind energy in the central plains could be channeled along existing railroad infrastructure to distribute the energy to distant urban centers while also powering the rail and trucking network.

Three Part Solution with Benefits beyond Sustainability

The e-Path Sustainable Transportation Concept is an infrastructure proposal with the goal and primary challenge of developing a plan to evolve North American (NA) freight transportation into a sustainable system that moves away from fossil fuels and toward a more efficient renewable energy. A key aspect of the plan is to leverage improvements in technology and configuration to provide economic advantages and public safety enhancements.

1. Providing Right-of-Way for High Power Transmission Lines

Wind energy throughout the rich central plains could be a key replacement for diesel in powering the rail network. The existing railroad corridors provide the infrastructure necessary to harvest the wind energy and channel it across electric power lines.

2. Electrifying North American Rails

Facilitating electrification of the North American (NA) rail network is a requirement for evolving the NA freight transportation system into a sustainable, efficient, and safe network. European main line rail is predominately electrified offering substantial efficiencies, around 2.5 times the diesel powered NA rail network. In addition to energy efficiency, electrification allows renewable to be utilized to provide a drastic reduction in transportation related CO2 production.

The Autonomous Rail Vehicles

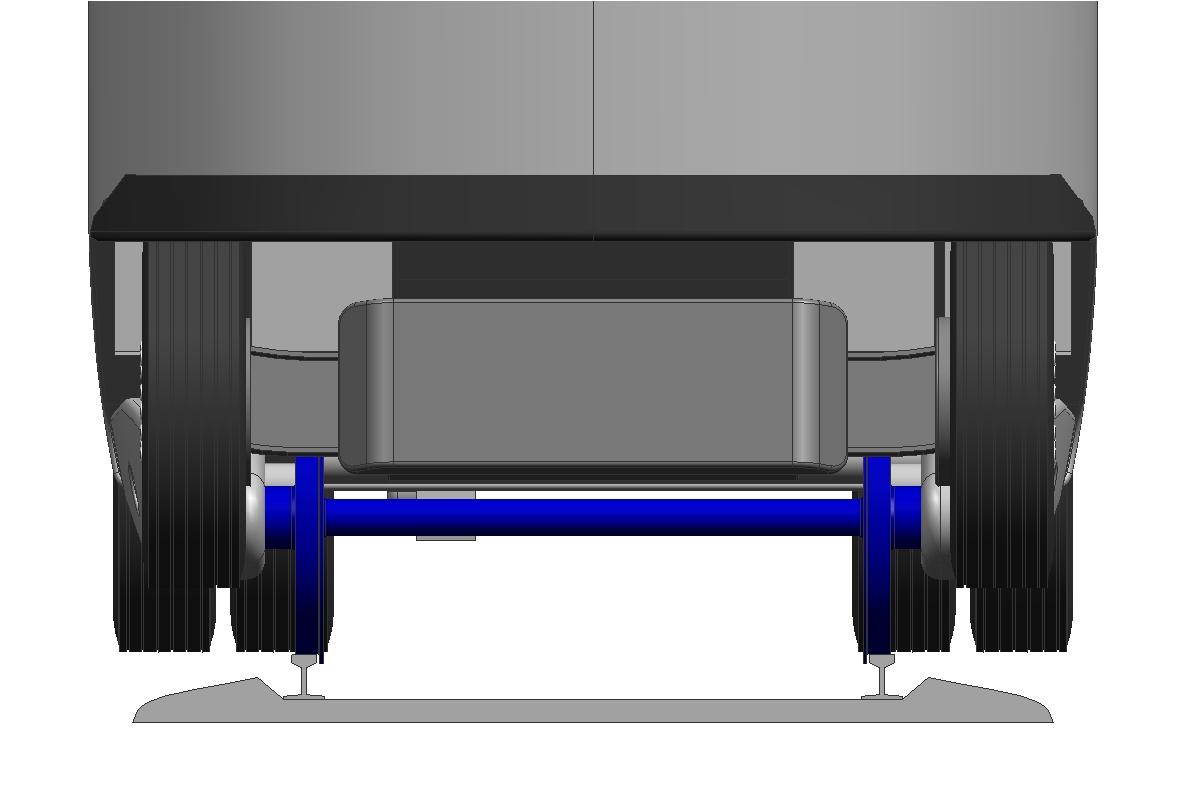

The vehicles draw power from suspended catenary lines through a deployable pick-up assembly housed in the front of the vehicle. A relatively small battery pack would allow the carriage to move under its own power when entering or leaving the rails at intermodal yards. The rear tires of the carriage are powered via electric motor housed near the wheels. The suspension of the rear tires can vary their load carrying duty pneumatically. Two forward tires are used to steer the carriage when it is under its own power and to support the front end of the carriage as it awaits pick up by a tractor for local delivery. The four steel wheels are deployed when the carriage is over the rails and the tires are retracted to transfer the load from the tires to the steel wheels. One of the rear powered axles (but only 2 of the 4 tires) remains in contact with the rail but only enough to provide sufficient traction for motion.

The amount of weight on the tires is automatically modulated based on the need for traction. This mitigates the amount of friction loss induced by tires. This variable traction system would also accommodate regenerative and emergency braking. On tracks that approach a railroad crossing, the addition of a curb on the outer sides of the rails running a maximum train length before the crossing provides an additional means to stop a large group of carriages running in a close pack. In the event the lead carriage senses an object in the path after the gates are down it would send a signal to all of the carriages in the caravan to begin emergency braking. This would drop all of the tires down into contact with the curb thus providing a stopping distance comparable with a highway truck as opposed to a train.

3. Electrifying Commercial Trucking Transit

By leveraging an electrified rail network to provide an evolutionary pathway to fully autonomous intermodal rail service, the e-Path Sustainable Transportation Concept also introduces a means to electrify commercial trucking. The intermodal carriages carry their own electric drive train that powers the rear set of wheels. 4 deployable, low friction steel wheels carry the weight when on rails. Initially, carriages would be towed on roads with conventional truck tractors. However, next generation tractors could be developed to leverage the electromotive drive train in the rear of the trailer, and in doing so provide a more efficient form of motive power than is possible with trucks driving on tires on the highway.

The Autonomous Carriages

The autonomous carriages would negate the need to compile and break down trains at the switch yard. Intermodal yards can now be nothing more than a spur track and a parking lot. This would allow a vast increase in viable rail induction points with little investment in new infrastructure required of traditional trains. As carriages enter & leave the rail line at more numerous points, greater economic efficiency would occur because of improvements in timing and location. This would induce a financial incentive that would drastically reduce the amount of long haul trucks on the highways, thus reducing the environmental cost and improving public safety.

Trains vs Trucks

The US Transportation Energy book states that rail freight uses approximately 1/10 the energy per pound required of trucking freight. Because of this, moving freight off of highways and onto the rails is of the utmost importance in improving efficiency. However, the delivery flexibility that trucking provides over rail makes it impractical to achieve substantially higher rail usage without rethinking how we access the rail network. Even with the efficiency gained through the use of intermodal methods, a train must be compiled into an assembly of coupled cars that is inherently inflexible from a scheduling and logistical standpoint.

New developments in communications, sensing and networking technologies could be applied to form an automated rail network that would fundamentally alter our notion of rail transit. Trains are currently very limited in their ability to avoid hazards even though they are driven by a person. Truck related accidents on highways still claim numerous lives every year and a system to reduce the number of tractor trailers on the road would thus serve a major public good.

Interweaving separate design challenges to into a holistic transportation approach that benefits the environment, public safety and the economy.